Barksdale AFB Blast Cabinets

Barksdale AFB Blast Cabinets

Barksdale AFB Blast Cabinets

November 04, 2022 AFG installed two of our GEN-3 Abrasive Blast Cabinets at Barksdale.

Eglin AFB Air Showers

Barksdale AFB Blast Cabinets

Barksdale AFB Blast Cabinets

September 12, 2022 AFG was awarded the contract to design, fabricate and install an Air Shower Transition area at Eglin AFB. This air shower will support the F-35 paint booth and mitigate the escape of Hexavalent Chromium from the booth as the workers exit the booth

MacDill AFB Florida

Barksdale AFB Blast Cabinets

MacDill AFB Florida

September 12, 2022 AFG was awarded the contract to provide MacDill AFB with two (2) GEN-3 abrasive blast cabinets. These blast cabinets will be replacing the older Abrasive Blast Systems (ABS) cabinets

Lackland AFB

Barksdale AFB GEN-3 Blast Cabinets

MacDill AFB Florida

September 09 2022 AFG was awarded the contract to provide Lackland AFB with one GEN-5 Walk-In Abrasive Blast Booth

New Hampshire Air Guard

Barksdale AFB GEN-3 Blast Cabinets

Barksdale AFB GEN-3 Blast Cabinets

July 2022 AFG was awarded the contract to provide New Hampshire Air Guard corrosion Shop one (1) GEN-3 abrasive blast cabinets

Barksdale AFB GEN-3 Blast Cabinets

Barksdale AFB GEN-3 Blast Cabinets

Barksdale AFB GEN-3 Blast Cabinets

June 2022 AFG was awarded the contract to provide Barksdale AFB corrosion Shop two (2) GEN-3 abrasive blast cabinets

Wright-Patterson AFB Blast Booth

Wright-Patterson AFB Blast Booth

Wright-Patterson AFB Blast Booth

March 16, 2022 AFG was awarded the contract to design, fabricate and install a new Abrasive Blast Booth with Air-Shower

Laughlin AFB Sunshade Maintenance

Laughlin AFB Sunshade Maintenance

Laughlin AFB Sunshade Maintenance

September 25 2021 Aerospace Facilities Group (AFG) was awarded a five year contract to maintain the flight-line Sunshades in support of the T-38's

Luke F-35 Sunshade Maintenance

Laughlin AFB Sunshade Maintenance

Laughlin AFB Sunshade Maintenance

September 25 2021 Aerospace Facilities Group (AFG) was awarded a five year contract to maintain the flight-line Sunshades in support of the F-35 Program

Dyess AFB Blast Cabinets

Laughlin AFB Sunshade Maintenance

Illinois Air Guard Blast Cabinet

September 17 2021 Aerospace Facilities Group (AFG) was awarded the contract to supply two (2) Gen-3 Abrasive Blast Cabinets to Dyess AFB in support of the B-1 Bomber Project

Illinois Air Guard Blast Cabinet

Minot AFB Blast Booth & Paint Booth

Illinois Air Guard Blast Cabinet

September 16 2021 Aerospace Facilities Group (AFG) was awarded the contract to supply the Illinois ANG with two GEN-3 Abrasive Blast Cabinets

Altus AFB Blast Booth

Minot AFB Blast Booth & Paint Booth

Minot AFB Blast Booth & Paint Booth

August 30 2021 Aerospace Facilities Group (AFG) was awarded the contract at Altus AFB Oklahoma to provide a new Abrasive Blast Booth and Air Shower

Minot AFB Blast Booth & Paint Booth

Minot AFB Blast Booth & Paint Booth

Minot AFB Blast Booth & Paint Booth

July 30 2021 Aerospace Facilities Group (AFG) was awarded the contract at Minot ND AFB to provide a new Abrasive Blast Booth, Air Shower, Sanding Booth and Paint Booth

Luke AFB Blast Booth & Air Shower

Luke AFB Blast Booth & Air Shower

Luke AFB Blast Booth & Air Shower

July 16 2021 Aerospace Facilities Group (AFG) was awarded the contract to design, manufacture, and install a new abrasive blast booth and Air Shower at Luke AFB Arizona in support of the F-35 program

Andersen AFB Guam

Luke AFB Blast Booth & Air Shower

Luke AFB Blast Booth & Air Shower

July 02 2020 Aerospace Facilities Group (AFG) was awarded the contract to design, build, and install one large abrasive blast booth, one large paint booth and two smaller paint booths at Andersen AFB Guam in support of the US Navy Helicopter program

Dyess AFB

Luke AFB Blast Booth & Air Shower

Dyess AFB

July 16 2021 Aerospace Facilities Group (AFG) was awarded the contract to design, manufacture, and install a new abrasive blast booth and Air Shower at Dyess AFB Texas in support of the B-1 program.

US Navy

Mississippi ANG Helicopter Booth

Dyess AFB

July 10, 2019 AFG was awarded the contract to replace the older Pauli System media recovery floor and Rotary Selector with a new AFG full floor recovery including our media recovery slide gate system at the Norfolk Naval Ship Yard.

Andersen AFB Guam

Mississippi ANG Helicopter Booth

Mississippi ANG Helicopter Booth

June 05, 2019 AFG awarded a contract to provide an abrasive blast booth and three paint booths for the US Navy at Joint Base Andersen Guam. The booths will be used to service CH-47 and other helicopters for the Navy.

Mississippi ANG Helicopter Booth

Mississippi ANG Helicopter Booth

Mississippi ANG Helicopter Booth

May 21, 2019: US Army getting ready to abrasive blast the CH-47E helicopter in the newly commissioned helicopter blast booth constructed by AFG. AFG equipped the booth with air operated side lift to allow the maintenance crews to move freely up and down and provide full-length access to the air frame while blasting.

May 13, 2019: Aerospace Facilities Group was awarded the contract to supply the US Army at the Corpus Christi Army Depot with seven (7) of our GEN-3 Abrasive Blast Cabinets. These cabinets will be used in support of the helicopter maintenance at the base.

Blast cabinets will have our Ergo-Design, turntables with carts to assist in getting parts in and out of the cabinets.

May 02, 2019: Aerospace Facilities Group was awarded a monthly five-year contract at Eglin AFB Florida to maintain the C-130 paint booth and smaller paint booth at the test and evaluation side of the base. Maintenance includes; filter changes, therm graphic imaging of motor starters, vibration analysis of exhaust fans, air make-up unit maintenance.

March 22, 2019: Aerospace Facilities Group was awarded the contract to design, fabricate, and install one abrasive blast booth and two paint booths at Andersen AFB Guam in support of the Navy's SH-60 Seahawk, and MH-53 Sea Dragon helicopters.

A new corrosion facility is being built to house the 28' foot wide x 70' foot long x 26' foot high abrasive blast booth and paint booth. The paint booth will be temperature and humidity controlled for painting operations

In addition to the large abrasive blast and paint booth, there will also be a smaller paint booth 40' foot Long x 15' foot wide and a paint mixing and storage room.

December 03, 2018: Aerospace Facilities Group was awarded a five (5) year maintenance contact for Al Udeid Air Base in Qatar.

This five-year maintenance contract covers all the corrosion control equipment designed, manufactured, and installed by AFG.

The equipment supports the on-going mission in the Middle East. Equipment includes

paint booths, blast booths, blast cabinets, dust collectors, tool compressors, breathing air compressors,

and breathing air purifiers.

October 01, 2018: Aerospace Facilities Group was awarded the maintenance contract at Luke AFB to maintain the F-16/F-35 paint booths. This will be a monthly five-year maintenance service contract to support the corrosion and fabrication shop in direct support of the F-16 and F-35 fighters.

October 01, 2018: Aerospace Facilities Group was awarded a five-year maintenance contract at Columbus AFB. This maintenance contract is for the abrasive blast booth and facilities for aircraft. This contract is for monthly service to all the Abrasive Blast Equipment (PMB) at the base.

September 24, 2018: Aerospace Facilities Group was awarded the contract

to supply two of our GEN-3-XP Abrasive Blast Cabinets to Little Rock AFB. These

cabinets will be replacing the older Pauli Systems cabinets in the C-130 Corrosion Shop.

Both cabinets will be designed and manufactured as explosion-proof cabinets as they will be

installed in the C-130 paint booth area classified a Class-1, Div-1 explosive zone.

September 21, 2018: Aerospace Facilities Group was awarded the contract to supply

the New York Air National Guard with one of our personnel air showers for the new

corrosion shop facility.

This unit will allow the workers to get the hazardous contaminates off their

clothing prior to exiting the corrosion shop.

September 20, 2018: Aerospace Facilities Group was awarded the contract

to supply Eielson AFB in Fairbanks Alaska one of our GEN-3 Abrasive

Blast Cabinets.

September 18, 2018: Aerospace Facilities Group was awarded the contract to design,

manufacture, and install one of our GEN-3 Abrasive Blast Cabinets for Hickham AFB Hawaii.

This cabinet will be specifically built for shot peening with a ceramic shot.

The cabinet and cyclone will be lined with our Blast Shield™ to protect the cabinet interior and the cyclone separator from wear.

September 16, 2018: Aerospace Facilities Group was awarded the contract

to supply two (2) of our GEN-3 Abrasive Blast Cabinets to Hurlburt Field in Florida.

The cabinets will be used in support of the AC-130 corrosion shop and replace the older

Pauli Systems cabinets.

September 14, 2018: Aerospace Facilities Group was awarded the contract to supply one of our personal air showers to Tinker AFB. These air shower will be used by the corrosion

shop to pre-clean their PPE prior to removing it and going into the dirty/cleanroom.

September 12, 2018: Aerospace Facilities Group was awarded the contract for two (2) of GEN-3 abrasive blast cabinets to Charleston AFB. One cabinet will be designated for Aluminum substrates and the other cabinet for steel substrates.

August 31, 2018: Aerospace Facilities Group putting the finishing touches on the new CH-47 Helicopter Abrasive Blast Booth for the Army. The facility will be used to strip aircraft coatings using plastic media. The AFG Side Lifts allow the workers to travel up and down and the full length of the booth, thus eliminating the need for work stands within the booth.

August 25, 2018: Aerospace Facilities Group, Inc. was awarded the contract to replace the Breathing Air Systems at Columbus AFB. This new system will be designed and installed at the Abrasive Blast facility at Columbus AFB.

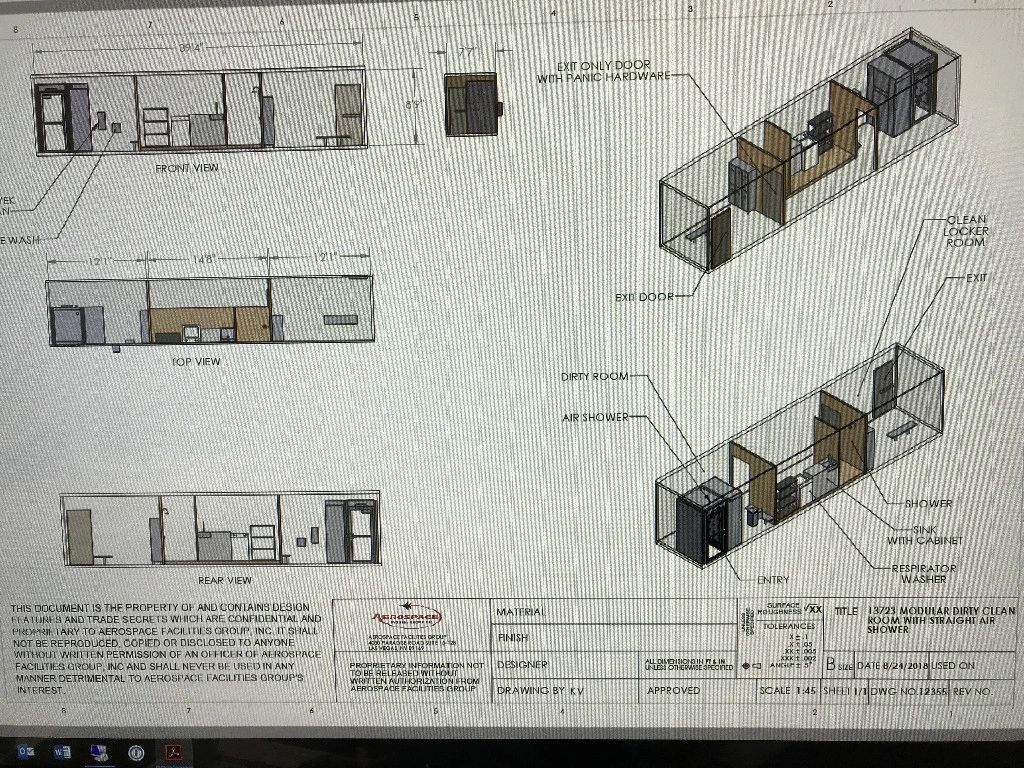

August 20, 2018: Aerospace Facilities Group, Inc. was awarded the contract to design, fabricate and install a dirty cleanroom system at Tinker AFB. This system will be a stand-alone modular unit to allow the personnel working within the corrosion hangar to exit the building, go into the AFG dirty/clean module, step into AFG's Air Shower to remove the media and dust from their Tyvek suits, remove their PPE gear, wash their respirators and hands, shower and change into there regular duty clothes. AFG's system helps mitigate the spread of Hexavalent Chromium outside of the controlled workspace.

August 16, 2018: Aerospace Facilities Group, Inc. was awarded the contract to

provide two of our GEN-3 Abrasive Blast cabinets to the USAF, specifically the new USAF

Advanced Technology and Training Center in Middle Georgia (Robins AFB). This contract is in conjunction with Wright Patterson AFB and the University of Ohio Advanced Research Center.

.jpg/:/cr=t:11.54%25,l:0%25,w:100%25,h:76.92%25/rs=w:814,h:407,cg:true)

Copyright © 2023 Aerospace Facilities Group, Inc. - All Rights Reserved.

Powered by GoDaddy